Vibrating Feeder

We are leading Electromagnetic Vibrating Feeder, Manufacturers, Suppliers and Exporters located in Ambarnath MIDC Dist Thane, Maharshtra India.

Vibrating feeders play a crucial role in various industries, including mining, food processing, and pharmaceuticals, among others. These machines enable the smooth and efficient transfer of bulk materials from one point to another, ensuring a seamless workflow in the production process. As a leading manufacturer of vibrating feeders in India, Mitool Equipments offers a range of specialized products, including electromagnetic vibrating feeders and electromechanical vibrating feeders. This article highlights the unique features of these feeders, the benefits they offer, and their applications across different industries.

Vibrating feeders are material handling devices designed to convey bulk materials in a controlled manner. They use vibrations generated by an electromechanical or electromagnetic system to move materials along a predefined path. By adjusting the frequency and amplitude of the vibrations, the rate at which the materials are transported can be controlled with precision. Some of the primary advantages of using vibrating feeders include reduced labor costs, enhanced efficiency, and minimized material wastage.

Electromagnetic Vibrating Feeders

Electromagnetic vibrating feeders utilize the principles of electromagnetism to generate vibrations. These feeders are characterized by their high precision and their ability to handle fine and granular materials. Some of the key features of electromagnetic vibrating feeders include:

a. Precision Control: Electromagnetic feeders offer excellent control over material flow, allowing for accurate and consistent dosing of bulk materials. By varying the voltage supplied to the electromagnet, the feed rate can be adjusted to meet the specific requirements of different applications.

Low Maintenance: With no moving parts, electromagnetic feeders require minimal maintenance. This not only reduces downtime but also lowers operational costs.

c. Energy Efficient: Electromagnetic vibrating feeders consume less power compared to other types of feeders, making them a cost-effective solution for businesses looking to reduce their energy consumption.

d. Versatile Applications: These feeders are suitable for a wide range of industries, including food processing, pharmaceuticals, chemicals, mining, and recycling.

Electromechanical Vibrating Feeders

Electromechanical vibrating feeders use a combination of mechanical and electrical components to generate vibrations. These feeders are ideal for handling heavy-duty materials and are characterized by their robust construction and high-capacity capabilities. Key features of electromechanical vibrating feeders include:

a. Durable Design: Electromechanical feeders are built to withstand harsh operating conditions, making them suitable for heavy-duty applications such as mining, construction, and quarrying.

b. High Capacity: These feeders can handle large volumes of material, ensuring that production processes are not disrupted due to material shortages.

c. Adjustable Feed Rates: Electromechanical feeders allow operators to adjust the feed rate based on the material characteristics and the requirements of the application, ensuring optimal performance.

d. Low Noise Operation: The advanced design of electromechanical vibrating feeders results in minimal noise pollution, making them ideal for applications where noise reduction is a priority.

Mitool Equipments is a renowned manufacturer and supplier of high-quality vibrating feeders in India. With years of experience and expertise, the company is committed to providing reliable and durable solutions tailored to meet the unique requirements of its customers. Some of the reasons why Mitool Equipments is the go-to choice for vibrating feeders include:

a. Customized Solutions: Mitool Equipments understands that different industries have different needs, and therefore offers custom-designed vibrating feeders to cater to specific requirements.

b. Quality Assurance: The company uses only the highest quality materials and components in the manufacturing of its vibrating feeders, ensuring longevity and durability.

c. Expertise: Mitool Equipments boasts a team of skilled engineers and technicians who have in-depth knowledge of vibrating feeder technology, enabling them to deliver innovative and efficient solutions.

d. Excellent Customer Support: The company is committed to providing exceptional customer service, offering comprehensive after-sales support, and ensuring that its customers enjoy a hassle-free experience.

e. Competitive Pricing: Mitool Equipments provides high-quality vibrating feeders at competitive prices, making them an affordable solution for businesses of all sizes.

Applications of Vibrating Feeders in Different Industries:

The versatility of vibrating feeders makes them an essential component in various industries. Some of the common applications include:

Vibrating feeders are versatile material handling devices that find applications in a wide range of industries, including cement, power, construction, foundry, FMCG, and plastic industries. They facilitate the smooth and efficient transfer of bulk materials, enhancing overall productivity and efficiency. Here, we outline the applications of vibrating feeders in each of these industries:

1) Cement Industry

In the cement industry, vibrating feeders play a crucial role in transporting raw materials such as limestone, clay, and gypsum, from storage silos to crushers, mills, and other processing equipment. They also help distribute the processed materials evenly onto conveyor belts or directly into trucks for transportation to distribution centers. By ensuring a consistent flow of materials, vibrating feeders help maintain the desired quality of the final cement product and optimize the production process.

2) Power

Vibrating feeders are widely used in the power industry, particularly in coal-fired power plants. They help transport and dose coal and other solid fuels to furnaces and boilers for combustion. Additionally, vibrating feeders are used to handle ash and other residues generated during combustion, ensuring their efficient removal and disposal. This not only helps maintain a clean working environment but also minimizes the risk of accidents and equipment breakdowns.

3) Construction Industry

In the construction industry, vibrating feeders are employed to handle and transport various raw materials, such as sand, gravel, and crushed stones. They are also used to transfer processed materials, like cement and concrete, to different stages of the construction process. By providing a consistent supply of materials, vibrating feeders enable construction projects to proceed smoothly and efficiently.

4) Foundry Industry

Vibrating feeders play a vital role in foundries by transporting, dosing, and mixing raw materials such as sand, metal, and binders for the production of molds and castings. They also help separate and transfer different types of metals, alloys, and slag for further processing or disposal. By automating these processes, vibrating feeders contribute to a safer and more efficient working environment, reducing the need for manual labor and minimizing the risk of accidents.

5) FMCG (Fast-Moving Consumer Goods) Industry

In the FMCG industry, vibrating feeders are employed to transport and dose various ingredients and products, such as grains, powders, and liquids. They are also used to sort and package finished products, ensuring a consistent flow of goods through the production line. By automating these processes, vibrating feeders help maintain product quality, minimize wastage, and optimize production efficiency.

6) Plastic Industry

Vibrating feeders are extensively used in the plastic industry for various applications, such as transporting, dosing, and mixing raw materials like plastic pellets, resins, and additives. They also facilitate the separation and transportation of recycled plastic materials for further processing. By automating these processes, vibrating feeders help plastic manufacturers maintain product quality, reduce labor costs, and enhance overall operational efficiency.

In conclusion, vibrating feeders are essential tools in numerous industries, ensuring the efficient and controlled transfer of bulk materials throughout the production process. Their versatile nature and adaptability make them ideal for a wide range of applications, from cement and power to construction, foundry, FMCG, and plastics. By automating material handling processes, vibrating feeders contribute to improved productivity, reduced labor costs, and enhanced overall efficiency across various industrial sectors.

Vibrating feeders are indispensable tools in many industries, ensuring the efficient transfer of bulk materials and improving overall productivity. Mitool Equipments, a leading manufacturer in India, offers both electromagnetic and electromechanical vibrating feeders designed to cater to the unique needs of various industries. With their commitment to quality, innovation, and customer satisfaction, Mitool Equipments is the ideal choice for businesses looking to invest in state-of-the-art vibrating feeder technology.

VIBRATORY MOTORS

Mitool Vibratory Motors used in Vibro feeders are totally enclosed 3 phase, squirrel cage induction motors with adjustable, eccentric weights mounted on the extended shaft to set up vibrations during rotation. The design of shaft and the selection of bearing has been carefully done to withstand heavy radial loads. Two identical motors mounted parallel to each other on a right and left, which is free to move in clockwise or anticlockwise directions, will produce linear vibrations.

Both motors

must rotate in opposite direction to each other. This principle is adopted for handling large bulky material in large feeders.

Base Mounting

Suspension Mounting

CONSTRUCTION

Mitool Vibrating electromechanical feeders can be supplied with base mounted type of suspension or one end suspension & one end base and vice versa.

These electromechanical feeders are having a tray mounted on the drive units. This drive unit is located beneath the tray or on top of the tray in special case.

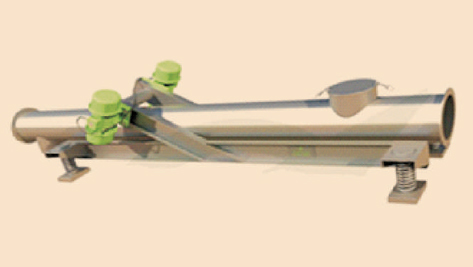

Tubular Vibratory Feeder

Mitool Tubular Feeders ensure that all the material is safely transferred from the feed hopper to the required destination.Available in round or square sections , Mitool Tubular Feeders are manufactured in a range of 160 mm dia to 500 mm dia and in lengths of from 1 meter to 5 meters.

Tubular Vibratory Feeder can be operated by vibratory motors or electromagnetic drive units Mitool Tubular Feeders can be operated at tube angles from 100 up hill to 150 down slope only in motorised Tubular Feeder.

WORKING PRINCIPLE

Mitool tubular vibrating feeder is an important inertial-vibrating conveyor. It has simple structure and various forms and specification, which can meet the demand of short and intermediate transportation of all kinds of small block, granular and powder material, widely used in different environment in various industries.