Permanent Suspension Magnets

>

>

Operating height & belt width are the main aspect for selection. As per standard available conveying systems, the suspension magnets are available for operating heights upto 300, 350 mm.

To recommend right magnet for right application, we recommend to share following details during enquiry.

• Application

• Belt speed

• Belt inclination

• Belt width

• Material properties

• Material Type

• Grain size

• Conveyed Material Temp

• Lump size

• Tramp iron Size (Dimensions &

Weight of largest piece)

• Magnetic strength

• Conveyor capacity

• Conveyor speed

Suspension Magnets, a safe and apt mechanism for removal of tramp iron, that flawlessly protects costly processing machinery by preventing sparks that cause fire and explosion. It helps to protect purity of the products. Undoubtedly, it has been the most effective way for the removal of unwanted ferrous particles from heavy burden depths of materials being conveyed on fast moving belts.

By matching the magnetic strength that of the corresponding size of the Electromagnet used for the same application and through other added advantages the Permanent Suspension Magnet has proved to be a step ahead than Electro Magnetic Suspension Magnet.

APPLICATIONS

• Non magnetic sections of vibratory feeders.

• Vibrating screens • Oscillating conveyors

• Chute systems • Over belt conveyors

FEATURES & BENEFITS

Protects crushers, conveyor belts & pulverizes

• Purifies end product by removing ferrous contamination

• Retrieves ferrous particles & thereby recovers scrap with

resale value

• Capacity to hold iron, if power fails

• No operational cost

• Easy to install

• Less maintenance required

• Powerful & reliable

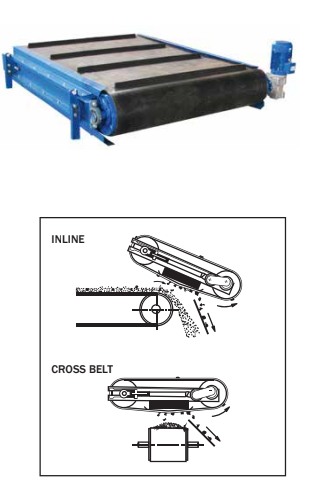

INSTALLATION

These magnets can be suspended either horizontally

(parallel to & above the conveyor) or suspended

at an inclination overhead pulley

• It can also be installed at the discharge point of the feeder

• Most preferred installation is over the head pulley for effective

extraction of material

PERMANENT OVERBAND MAGNETIC SEPARATORS

ADVANTAGES

• Magnetism is permanent

• Magnet operates at no extra cost

• Magnet holds iron if plant power fails

• No wiring for magnet

SELECTION

Permanent Overband Magnetic Separators are available to suit all standard conveyor widths for operating heights upto 300 mm. Trajectory will be calculated as per the Head Pulley Diameter & Belt Speed.

The Permanent Overband Magnetic Separator is an innovation with many advantages over the Electro Magnetic Overband Separator.

“MITOOL” Overband Magnetic Separator is effective for the continuous, automatic extraction & discharge of tramp iron from heavy burden depths of material being conveyed on fast moving belts.

APPLICATIONS

Overband Magnetic separators are utilized to separate ferrous material from non-ferrous materials for following applications:

PROTECTION:

Ensure safety of the process equipment such as crusher, pulverisers, conveyor belts etc. by removing tramp iron from the raw material under process and thereby prevent damage and sparks that cause fire and explosion.

PURIFICATION:

By removing iron contamination of non-ferrous material including end products purification process is conducted.

RECLAIMING:

Recover scrap with resale value by reclaiming ferrous materials

SALVAGING:

Valuable tools, machine parts, cutter tools etc. can be salvaged.

INSTALLATION

The Permanent Overband Magnetic Separator can be suspended over and ahead of the head pulley or almost anywhere along the conveyor line. Permanent Overband Magnetic Separator should be installed in such a way that it will cover Material Trajectory.

INSTALLATION

The Permanent Overband Magnetic Separator can be suspended over and ahead of the head pulley or almost anywhere along the conveyor line. Permanent Overband Magnetic Separator should be installed in such a way that it will cover Material Trajectory.

Application for all our Product is Same : Steel Plant , Cement Plants, Power Plants, Infra Structure, Pharamceutical, Chemical, Fertilizer, Cosmetic, Food, Packaging , Mines, Minerals, Waste management, Water Treatment Plant Recycling,