Vibrating Motors / Unbalanced Vibrating Motor / Unbalanced Vibratory Motor

We are leading Electromagnetic Vibrating Motor, manufacturers, suppliers and exporters located in Ambarnath MIDC Dist Thane, Maharshtra India.

Vibrating motors are essential components in various industrial processes and applications. They are employed in industries such as mining, construction, food processing, pharmaceuticals, and many more. In this comprehensive guide, we will delve into the world of vibrating motors, specifically focusing on electromagnetic vibrating motors and unbalance vibrator motors. Additionally, we will introduce you to Mitool Equipment, a leading manufacturer of these motors in India.

Vibrating motors are electromechanical devices that generate vibrations by converting electrical energy into mechanical energy. The primary function of these motors is to provide directional or linear movement to various equipment, making them crucial components in a wide range of applications. Vibrating motors are typically classified into two main categories: electromagnetic vibrating motors and unbalance vibrator motors.

Electromagnetic vibrating motors work based on the principle of electromagnetic induction, wherein a magnetic field is generated around a coil carrying an alternating current. This field interacts with the magnetic field of a magnet, producing a force that causes the motor to vibrate.

Key features of electromagnetic vibrating motors include:

1) Low maintenance: These motors have no brushes or commutators, reducing wear and tear and the need for regular maintenance.

Precision control: The vibration frequency and amplitude can be adjusted by altering the current flowing through the coil, allowing for precise control of the motor's vibration.

2) High efficiency: Electromagnetic vibrating motors have minimal energy losses due to their brushless design, resulting in high efficiency.

3) Unbalance vibrator motors, also known as eccentric mass vibrator motors, operate based on the centrifugal force generated by rotating unbalanced masses. The rotation of these masses produces a centrifugal force that results in the motor's vibration.

Key features of unbalance vibrator motors include:

1) Robust design: These motors have a simple and sturdy design, making them suitable for heavy-duty applications and harsh environments.

2) High torque generation: Unbalance vibrator motors can generate a high level of torque due to the presence of eccentric masses, resulting in powerful vibrations.

3) Wide range of applications: These motors are versatile and can be used in various applications, including material handling, screening, and compaction.

Mitool Equipment is a renowned manufacturer and supplier of high-quality vibrating motors, including electromagnetic vibrating motors and unbalance vibrator motors, in India. With a strong commitment to customer satisfaction and innovation, Mitool Equipment has established itself as a leading provider of vibrating motor solutions for various industries.

Applications of Vibrating Motors

Vibrating motors play a crucial role in various industries, including the cement, power, construction, foundry, FMCG (Fast-Moving Consumer Goods), and plastic industries. They are integral to a wide range of applications and processes, as detailed below:

1) Cement Industry

Vibrating motors are extensively used in the cement industry for various applications, including:

1.1. Material Handling: They facilitate efficient transport of raw materials, such as limestone, clay, and sand, through vibrating conveyors and feeders.

1.2. Screening: Vibrating screens with motors separate cement clinker particles based on size, ensuring product quality and consistency.

1.3. Silo and Hopper Discharge: Vibrating motors help in the effective discharge of cement from storage silos and hoppers by preventing material buildup and promoting uniform flow.

2) Power Industry

In the power industry, vibrating motors are used for:

2.1. Coal Handling: They assist in the transportation and screening of coal, ensuring a smooth and continuous supply to power plants.

2.2. Ash Handling: Vibrating motors help in conveying fly ash and bottom ash from combustion processes, facilitating efficient disposal or recycling.

3) Construction Industry

Vibrating motors play a pivotal role in the construction industry through applications such as:

3.1. Concrete Compaction: They help in consolidating concrete mixtures, removing air bubbles, and ensuring the strength and durability of structures.

3.2. Soil Compaction: Vibrating motors are used in compacting soil and granular materials, ensuring stable foundations for buildings and roads.

4) Foundry Industry

In the foundry industry, vibrating motors are employed for:

4.1. Sand Casting: They facilitate the compaction of molding sand around the patterns, ensuring accurate and detailed castings.

4.2. Shakeouts: Vibrating motors are used in shakeout machines to separate castings from sand molds, improving efficiency and reducing manual labor.

.3. Sand Reclamation: They assist in the mechanical reclamation process, where spent sand is cleaned, screened, and conditioned for reuse in molding and core-making.

5) FMCG Industry

The Fast-Moving Consumer Goods (FMCG) industry utilizes vibrating motors for:

5.1. Product Sorting and Grading: They help in sorting and grading products, such as fruits, vegetables, and packaged goods, based on size, shape, or weight, ensuring product quality and consistency.

5.2. Packaging: Vibrating motors facilitate the filling and compaction of products into packages, increasing efficiency and minimizing product waste.

6) Plastic Industry

In the plastic industry, vibrating motors find applications in:

6.1. Material Conveying: They aid in the transport of plastic granules, powders, and pellets through vibrating conveyors, feeders, and hoppers, ensuring a smooth flow of materials throughout the production process.

6.2. Screening and Separation: Vibrating motors are used in separating plastic materials based on size or density, ensuring product quality and purity.

6.3. Recycling: They play a role in the recycling process, where plastic waste is sorted, ground, and screened using vibrating equipment, promoting a sustainable approach to plastic use.

In conclusion, vibrating motors are essential components in various industries, including cement, power, construction, foundry, FMCG, and plastics. They contribute to the efficient handling, processing, and recycling of materials, as well as the improvement of product quality and consistency.

Vibrating motors, including electromagnetic vibrating motors and unbalance vibrator motors, play a crucial role in numerous industries and applications. Mitool Equipment, a leading manufacturer in India, offers high-quality and reliable vibrating motor solutions that cater to various industrial needs. With their state-of-the-art manufacturing facilities, experienced team, customized solutions, and comprehensive after-sales support, Mitool Equipment ensures that their customers receive the most efficient and suitable vibrating motor solutions for their applications.

UNBALANCE VIBRATOR MOTORS

Vibrator motors are robust, highly stable under load, having cylindrical roller Bearings Vibration resistant, high quality resin impregnated windings. End Shield fitted with rubber 0 rings to give dust tight and watertight enclosure. Quite running and require no maintenance.

Robust terminal board, cable wire cast in vibration resistant synthetic resin. Reliable high torque starting, Absolutely secure fixing of our of balance weights only the inner weights are adjustable, with legible markings on the weights.

Application

Vibrating Conveyors, Vibrating Screens, Conveyors Troughs and Tubes, Fields of Application: Coal, Lignite, Salt, Synthetic, Rubber, Fertilizers & Chemicals.

Technical Data & Dimensions

| Centrifugal force range | from 1830 to 122850 N. |

| Working moment | from 3.7 to 2250 kgcm. |

| Suitable for Vibrator units with useful weight range | from 3.5 to 5500 kgs. |

| Power Supply | 415 Volts, 3 phase, 50 hz. |

| Rated output | 0.3 to 8.56 kw |

| Ambient temperature | upto 60° C |

| Type of enclosure | IP 55 |

| Insulation Class | 'F' Class |

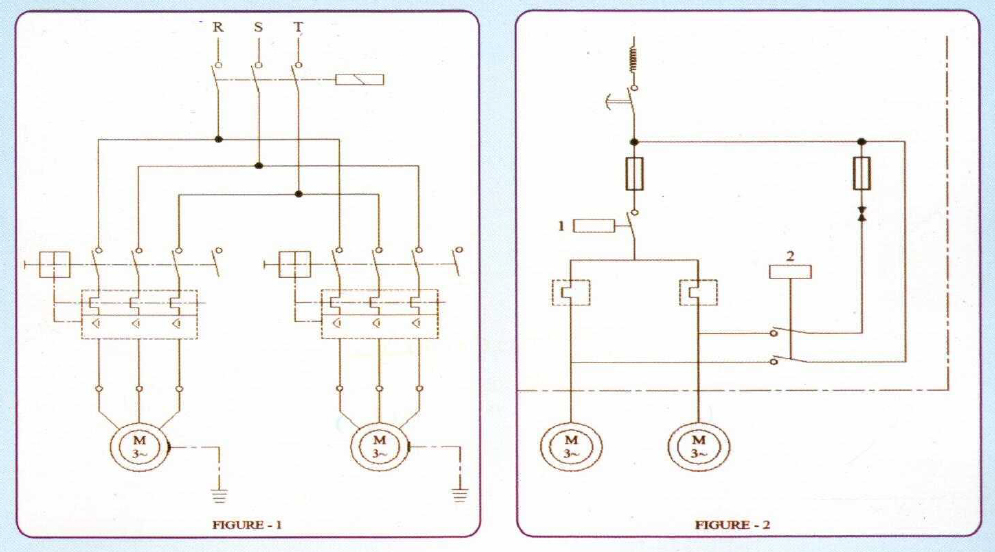

Power Supply and Connection Diagram

Vibration motors are connected to a three-phase system with flexible copper conductor cable. Connection can be effected as per (fig. 1) in the simplest manner by means of a common contactor, which must be interlocked by means of auxiliary contacts. We strongly recommend use of a circuit breakerwherevertwo motors are used

On the other hand, with the latter connection, considerable oscillation occur, on the disconnection of the equipments, due to the fact that resonant frequencies of the support springs will have a comparatively slow run trough, especially at a time when the trough is empty and the bulk material is absent. Forthis reason, a connection ofthe motors via a break unit, (Fig, 2) with which the motors can be brought to a standstill through d.c. breaking in a period of one to two seconds, is recommendable.